Sacramento

X-Ray Inspection

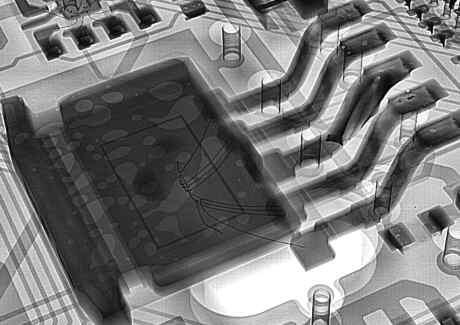

Sacramento X-Ray Inspection emerged from a need for testing in our own PCB production line. Our service employ 2D and 3D imaging technologies to accurately identify assembly defects and perform in-depth analysis on PCBs, ensuring swift and consistent inspections powered by YXLON Cheetah EVO technology.

CONTACT US FOR A QUOTE

Sacramento X-Ray Inspection is a division of Ansync Labs headquartered in El Dorado Hills, California.

We use the several types of X-ray inspections; each offers unique advantages when screening for defects.Type of X-Ray Inspections

2D Inspection

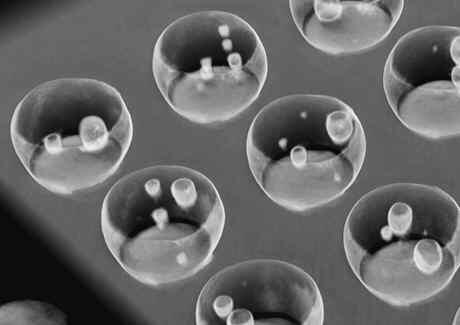

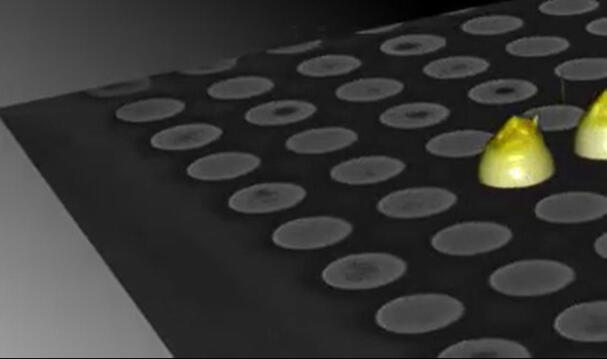

2D X-ray imaging is effective at spotting PCB assembly glitches, giving a clear view of all board layers at once without any damage. It's key for checking soldering on parts like BGAs, LGAs, and QFNs, which are tough to inspect with basic methods like microscopes. This technique is good for finding and measuring issues like solder bridging and solder voiding, making sure the PCB meets specifications.

CT Scan

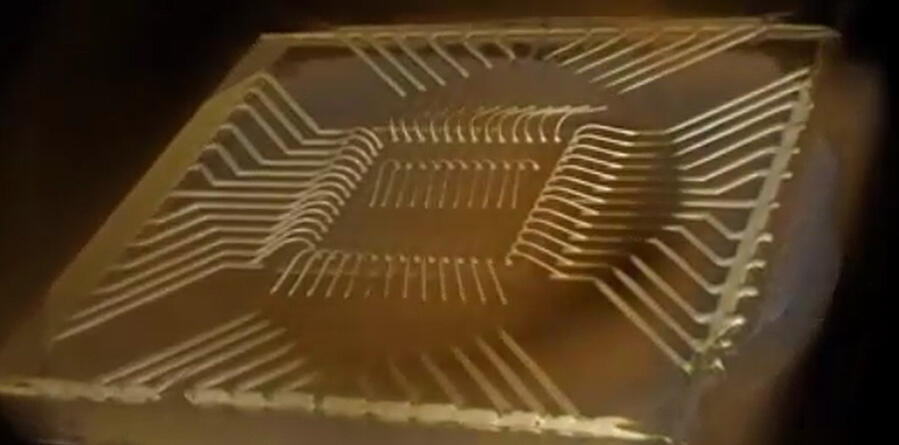

3D CT imaging is an effective method for both identifying and analyzing defects in a PCB and its components. It examines each layer separately, detecting issues like disconnects or delamination. It's useful for measuring the solder fill on different components and assessing factors like bond wire defects. Moreover, it can generate a full 3D view of a component, revealing its inner workings. However, the process requires the sample to be mounted and rotated, making it better suited for small, lightweight samples.

Laminography

3D Laminography imaging gathers similar data to CT imaging, but it's quicker and works well for larger, heavier samples. However, it doesn't match up to CT when it comes to image clarity and there's more image noise. The process involves placing the sample on a rotating table, taking 2D images at almost every angle, which are then combined to create a single 3D model.

YXLON Cheetah Evo

To meet our electronic testing demands, we sourced the superior imaging technology of YXLON Cheetah EVO. YXLON's strengths lie in offering cutting-edge 2D and 3D inspection capabilities, specifically Laminography and Computed Tomography (CT). Discover more about the YXLON Cheetah EVO here.

Blog

Ansync Labs Honored with Ecosystem Builder Award

Ansync Labs, the parent company of Sacramento X-Ray Inspection, recently was honored with the Ecosystem Builder Award at the GFX2023 Backyard Awards. This is a big shoutout to groups that pour in effort, time, and smarts to grow a vibrant entrepreneurial scene, benefiting both startup founders and the larger community in the Sacramento region.Nestled in Northern California, Ansync Labs is all about design for manufacture. They bring a variety of skills to the table to create solutions, fine-tune them, and make products come alive. Their squad of electrical, software, and mechanical engineers, backed by an in-house workshop and electronics assembly line, is on a mission to deliver practical solutions. They dive into stuff like motors and automation, medical gear, and IoT devices, aiming to make a positive dent in these fields.The GFX2023 Backyard Awards, brought to life by Growth Factory and backed by Stoel Rives, is a cool initiative that shines a light on the awesome work happening locally, especially around the Greater Sacramento area. In a world that often zooms in on global drama, this event zooms out to celebrate the solid work happening right in our backyard.Scoring the Ecosystem Builder Award is a sweet reminder of how crucial our goal is to amp up the entrepreneurial vibe in the region. It’s not about reaching a final destination, but marking a noteworthy milestone that pumps us up to keep pushing forward. It’s also a solid example for other organizations, showing off the potential to make positive waves in our local entrepreneurial scene. While we're stoked about this recognition, it fires us up to continue our hustle, fostering a supportive space for entrepreneurship in our community, and working towards a brighter, more innovative tomorrow for everyone.

Blog

Getting It Built: Moving from Prototype to Production

Navigating the dynamic startup ecosystem, the journey from prototype to production often appears formidable. This intricate pathway is laden with numerous elements ranging from securing essential capital to orchestrating supply chains. Sam Miller, the brainchild behind Ansync Labs, enlightened the Startup Grind Sacramento audience through his discourse titled, 'Getting It Built: Transitioning from Prototype to Production.' Here’s a distillation of his insights:Tackling the Funding and Marketing Maze:

Miller elucidates that startups frequently grapple with the challenge of accruing adequate funding. Common missteps include underestimating the requisite budget or depleting resources prior to goal realization. The antidote? A well-thought-out financial blueprint that accounts for potential roadblocks and directional shifts.He accentuates that marketing is not a sideline endeavor; it's fundamental to the product evolution journey. A lucid understanding of your target clientele and the channels to engage them is imperative, necessitating airtight marketing and sales blueprints.Vendor Alliances: The Silent Pillar:

Miller underscored the criticality of forging robust vendor alliances. Whether it’s bespoke screws or sophisticated electronic paraphernalia, pinpointing the right vendor is a pivotal move. He champions a tactic that nurtures enduring, mutually rewarding vendor liaisons entailing thorough research, scrutiny, and sustained dialogue to uphold quality and dependability.The Equilibrium: Domestic vs. Overseas Production:

Is domestic or overseas production the way to go? Per Miller, a harmonious blend is the key. Labor-intensive segments of your product may find cost-effective solutions overseas, while complex or delicate components are preferably fabricated domestically. Evaluating factors like freight charges, tariffs, and quality assurance is crucial to align with your production ambitions and ethos.The Significance of Tolerances and Specifications:

According to Miller, a comprehensive and precise specification dossier is invaluable. Furnishing vendors with exact tolerances and specifications curtails misinterpretations, trims down expensive blunders, and ensures the product adheres to quality benchmarks. It's about eradicating ambiguities, averting potential complications down the line.Unveiling the 'Supply Funnel' Concept:

Miller demystified the 'Supply Funnel' concept, illustrating that products evolve through phases, transitioning from discrete components to sub-assemblies, and ultimately, to the completed product. Adept management of this funnel propels streamlined operations and quicker market entry. The game plan involves discerning outsource-able components, assembly logistics, and the final production locus, fine-tuning each supply funnel phase for efficacy and cost prudence.In summation, the odyssey from prototype to a production-grade product is indeed a grand endeavor. However, with astute planning, solid vendor affiliations, and a judicious balance of domestic and overseas production, startups can traverse this multifaceted expedition more proficiently. As Sam Miller aptly showcased, it transcends merely getting it built—it's about mastering the art of building it right.

Blog

Why PCB X-Ray Inspection is Crucial for Your ElectronicsIntroductionIn the rapidly evolving electronics industry, precision and reliability are paramount. As a key component, Printed Circuit Boards (PCBs) are the backbone of most electronic devices. Ensuring their integrity is vital, and this is where PCB X-Ray inspection comes into play. This article delves into the reasons why X-Ray inspection is crucial for electronics, focusing on how it upholds quality, reliability, and functionality.Understanding PCB X-Ray InspectionPCB X-Ray inspection is a non-destructive testing method that uses X-rays to view the internal features of a PCB without damaging it. This technique is particularly effective for inspecting solder joints and layers of multilayer PCBs, which are not visible to the naked eye.Key Benefits of PCB X-Ray Inspection1. Detecting Hidden Defects: With the miniaturization of components and the complexity of PCB designs, traditional inspection methods are often insufficient. X-Ray inspection can detect hidden defects such as solder bridges, voids, and misalignments that could lead to failures in the field.2. Enhancing Product Reliability: By identifying potential issues early in the manufacturing process, PCB X-Ray inspection helps in enhancing the overall reliability of the product. This is crucial for high-reliability sectors like aerospace, medical devices, and automotive electronics.3. Supporting High-Density Packaging: As electronic devices become more compact, they require high-density packaging. X-Ray inspection is essential for verifying the integrity of these densely packed components, ensuring they meet the required standards.4. Facilitating Complex Designs: Advanced electronics often involve complex PCB designs with multiple layers and intricate circuits. X-Ray inspection provides a detailed view of these layers, ensuring that each component is correctly placed and soldered.5. Cost-Effectiveness: By detecting defects early, X-Ray inspection reduces the need for rework or scrap, ultimately saving costs associated with manufacturing defects.6. Compliance with Standards: Many industries require compliance with specific quality standards. X-Ray inspection helps in meeting these standards by providing thorough and accurate inspections.Challenges and ConsiderationsWhile PCB X-Ray inspection is highly beneficial, it requires significant investment in equipment and trained personnel. Additionally, interpreting X-Ray images requires expertise, as it can be challenging to distinguish between normal and abnormal conditions in a PCB.ConclusionIn conclusion, PCB X-Ray inspection is a critical process in the electronics manufacturing industry. It ensures the highest quality and reliability of PCBs, which in turn reflects on the final product's performance. While it involves investment and expertise, the benefits in terms of product reliability, cost savings, and compliance with standards make it an indispensable part of modern electronics manufacturing. As technology continues to advance, the role of PCB X-Ray inspection will become even more vital in ensuring the integrity of electronic devices.

Blog

How X-Ray Inspection Ensures the Quality of PCBsIntroductionIn the intricate world of electronics manufacturing, Printed Circuit Boards (PCBs) form the backbone of a multitude of devices. As technology advances, PCBs have become more complex and compact, raising the stakes for quality assurance. This is where X-Ray inspection plays a pivotal role, emerging as a non-destructive and highly effective method to ensure the quality and reliability of PCBs.The Need for X-Ray Inspection in PCB ManufacturingPCBs are populated with a variety of components, including microchips and other electronic elements. The miniaturization of these components and the complexity of PCB designs can lead to challenges in detecting defects. Traditional inspection methods, such as visual inspection or automated optical inspection (AOI), while useful, have limitations, especially when it comes to inspecting hidden features like solder joints beneath components.How X-Ray Inspection WorksX-Ray inspection utilizes high-energy radiation to penetrate the PCB and capture images of its internal structures. This process generates a detailed view of the board, revealing aspects that are invisible to the naked eye. The technology behind X-Ray inspection is akin to medical radiography – it can identify issues like misalignments, voids in solder, and even minute cracks.Key Benefits of X-Ray InspectionX-Ray inspection brings several critical advantages to the table in PCB manufacturing:1. Deep Layer Inspection: It can inspect multiple layers of a PCB, essential for multi-layered boards where defects can occur at any layer.

2. Accuracy in Defect Detection: The method excels in detecting a range of defects, including bridging, insufficient solder, and component misalignment.

3. Non-Destructive Analysis: Unlike some testing methods, X-Ray inspection does not damage the PCB, making it ideal for quality control throughout the manufacturing process.

4. Time Efficiency: It enables rapid inspection of a board, thereby reducing production delays and improving throughput.Applications of X-Ray InspectionX-Ray inspection finds its utility in various aspects of PCB manufacturing:- Post-Soldering Inspection: This stage involves checking solder quality and component placement.

- Quality Control in High-Reliability Sectors: The technology is essential for industries where failure is not an option, like aerospace or medical devices.

- Reverse Engineering: It is also helpful in analyzing the construction of a PCB for redesign or improvement purposes.Challenges and ConsiderationsDespite its advantages, X-Ray inspection comes with its own set of challenges:While X-Ray inspection is highly beneficial, it requires significant investment in terms of equipment and training. Additionally, interpretation of X-ray images requires skilled technicians, as the complexity of PCBs can make analysis challenging.ConclusionIn conclusion, X-Ray inspection is a powerful tool in ensuring the quality of PCBs. Its ability to provide in-depth and accurate insights into the internal structures of PCBs makes it an invaluable asset in the electronics manufacturing industry. As PCBs continue to evolve in complexity, the role of X-Ray inspection in maintaining high standards of quality and reliability will only become more crucial.

Blog

YXLON Cheetah EVO: Revolutionizing Non-Destructive TestingIntroductionThe YXLON Cheetah EVO series stands at the forefront of non-destructive testing (NDT) technology. Renowned for its precision and reliability, this series is a key player in industries where even the smallest defect can have significant implications.Key Features1. Advanced Imaging QualityThe standout feature of the Cheetah EVO is its superior imaging quality. Equipped with high-resolution flat-panel detectors and a state-of-the-art X-ray tube, it provides exceptionally clear and detailed images. This is crucial in sectors like aerospace, automotive, and electronics, where identifying minuscule flaws is essential.2. VersatilityThe Cheetah EVO is designed to handle a variety of specimens, from tiny electronic components to larger mechanical parts. This flexibility is due to its adjustable settings and modular design, making it a versatile tool for diverse inspection needs.3. User-Friendly SoftwareAn intuitive interface is a significant benefit of the Cheetah EVO. It allows operators, regardless of their experience level, to efficiently use the system with minimal training, thereby enhancing productivity and reducing operational delays.4. Automation in InspectionWith automated inspection capabilities, the Cheetah EVO boosts throughput and ensures consistent inspection quality. It can autonomously execute complex inspection routines, thanks to advanced software algorithms and pre-set inspection processes.5. Enhanced SafetySafety is a critical aspect of X-ray inspection systems. The Cheetah EVO prioritizes operator safety with robust shielding and integrated safety interlocks, significantly reducing the risk of radiation exposure.Applications Beyond ManufacturingAlthough primarily used in manufacturing, the Cheetah EVO's applications extend to sectors like real estate and construction. It can be used for inspecting building materials, detecting structural defects, and ensuring the quality of electrical components, particularly in advanced constructions like smart homes.ConclusionThe YXLON Cheetah EVO series is a testament to the advancements in NDT technology. Its combination of high-resolution imaging, versatility, user-friendly operation, automated processes, and safety features make it an invaluable asset in a variety of industries. For those in need of dependable and efficient NDT solutions, the Cheetah EVO represents a leading choice.

PRESS RELEASE

Ansync Lab Launches State-of-the-Art X-ray Inspection Service for Comprehensive PCB AnalysisEl Dorado Hills, CA, October 22, 2023— Ansync Labs is proud to announce the launch of Sacramento X-Ray Inspection, a new X-ray Inspection Service, offering unparalleled PCB examination. Leveraging advanced 2D and 3D imaging technologies, and powered by the cutting-edge YXLON Cheetah EVO technology, this service is set to redefine standards in electronic testing. With a focus on identifying assembly defects and performing in-depth analysis, Ansync’s X-ray Inspection Service is poised to become an invaluable asset for quality assurance in electronics manufacturing in the Sacramento RegionFor more information about this service, visit SacramentoXrayInspection.comMedia Contact:

Rich Foreman

Chief Marketing Hero

Ansync Labs

rich.foreman@ansync.com

(916) 535-8996

About Us

Sacramento X-Ray Inspection is a division of Ansync Labs headquartered in El Dorado Hills, California. We serve the Northern California Region including Sacramento, Elk Grove, Roseville, Folsom, Rancho Cordova, Davis, Woodland, Citrus Heights, Rocklin, West Sacramento, Auburn, Lincoln, San Francisco, Oakland, San Jose, Berkeley, Palo Alto, Mountain View, Sunnyvale, Santa Clara, Redwood City, Menlo Park, Cupertino, Fremont, Hayward, San Mateo, Concord, Vallejo, Fairfield, Richmond, Daly City, San Rafael, Petaluma, Novato, Santa Rosa, Napa, Livermore, Pleasanton, Walnut Creek, Alameda, San Leandro, San Ramon

5090 Robert J. Mathews Parkway

El Dorado Hills, California 95762

To learn more about our PCB assembly service, visit sacramentopcbassembly.com

To learn more about our Prototype Development visit: SacramentoPrototypeShop.com